Manufacturing Overview: Progressive Die Stamping

Overview Of Progressive Die Stamping

For purchasing managers, engineering managers, and other key decision-makers within an OEM, sourcing parts and components that meet quality standards while also being competitively priced is crucial.

Depending on the specification of the part required and the application in which it will eventually be used, they will decide upon a manufacturing partner that has the capabilities and expertise to make the parts.

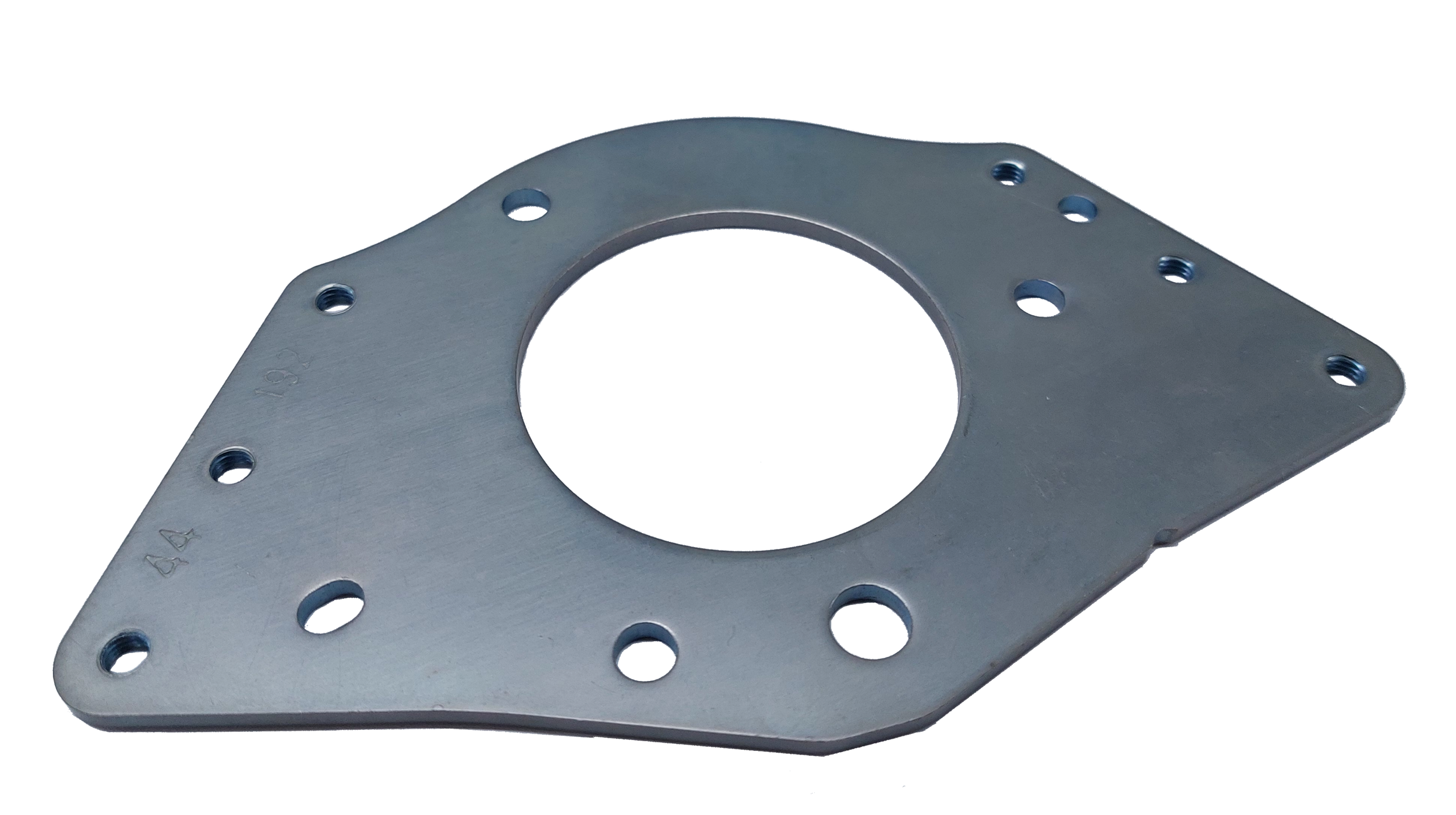

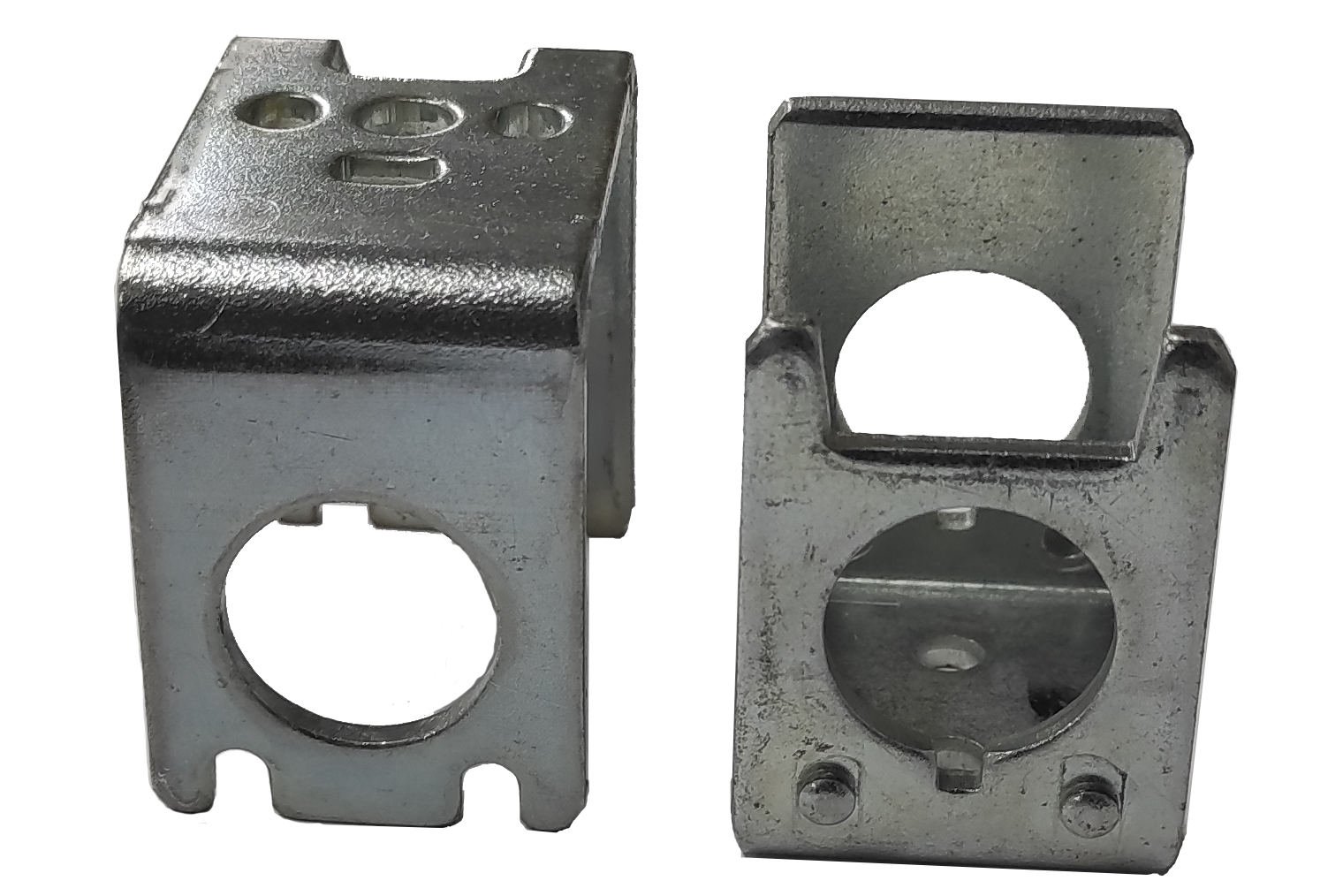

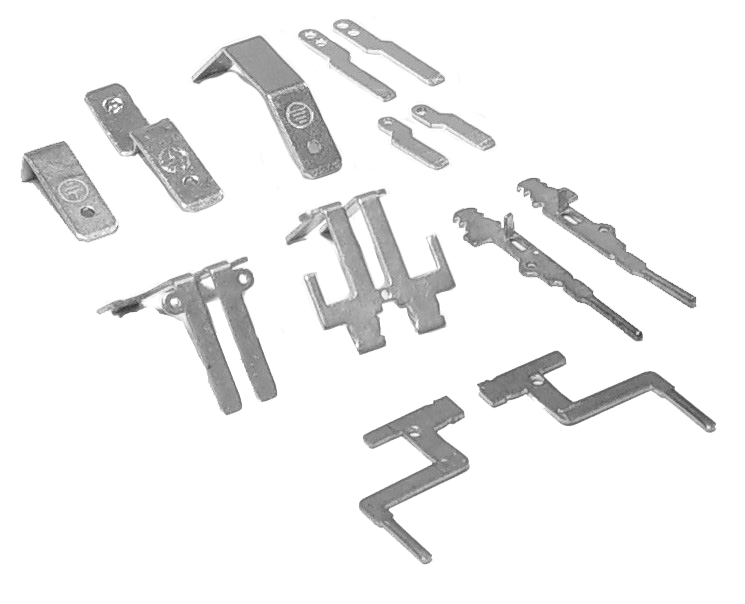

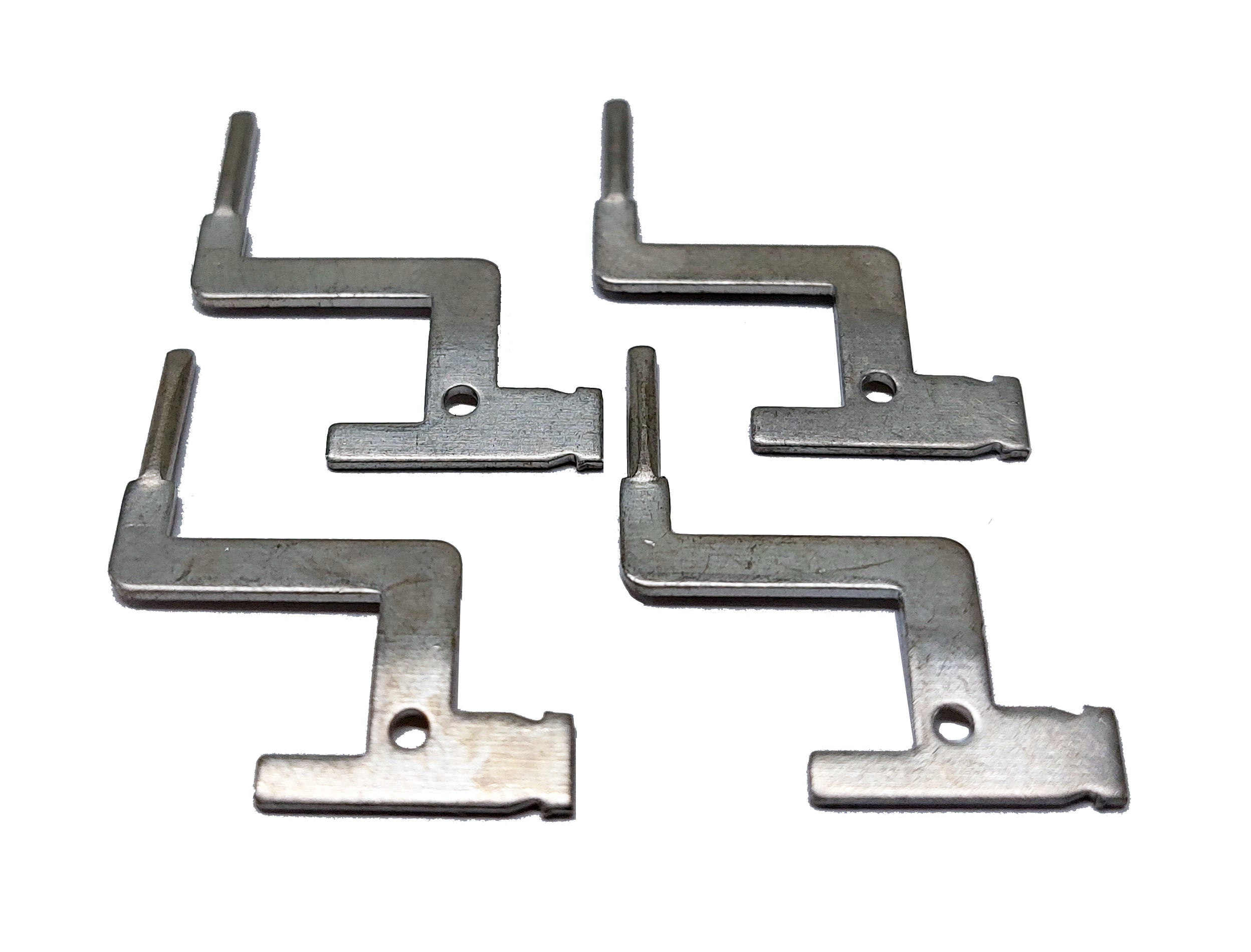

Progressive Die Stamping Parts

One widely utilised manufacturing method is Progressive Die Stamping. This is a Precision Metal Stamping method used for high quantity production runs, resulting in high accuracy parts, that often require complex profiles.

What Is Progressive Die Stamping?

commonly used metal stamping Method

3D Model of Progression Tooling Part

Progressive die stamping is a metal-forming process that can produce complex parts in multiple stages. Metal coils are fed through the various stations of an auto-transfer production line, each time a new feature is completed. A High-Tonnage Press Machine uses extreme pressure to dictate the shape of a part. These shapes can be made through the likes of bending, punching, forming, drawing and, coining.

High Volume, Low-Cost Manufacturing

The decision to produce parts with progressive die stamping comes down to several key requirements of the part such as size, complexity, and volumes required. Progressive die stamping is the go-to method of manufacturing to produce large volumes of parts while keeping costs as low as possible.

Progressive Die vs Transfer Die Stamping: what is a progressive die?

Progressive die stamping is specifically designed for high-volume production. Transfer die stamping is also good for high-volume production, it differs in that the part is separated from the metal coil during the first operation and then automatically transferred from station to station until the part is completed.

Our Progressive Die Stamping Machine Video

Advantages Of Progressive Die Stamping

Volume and Speed:

The Progressive die stamping process operates by having a continuous feed of material being moved through the stamping machine. Higher volumes of parts can be produced at faster speeds than other metal stamping methods.

Efficient Use of Material:

With the various methods for shaping the material (such as bending, punching, forming, drawing and, coining), a large portion of it is used, leaving minimal waste which is also attributed to lower manufacturing costs.

High Repeatability:

By using dedicated tooling, high volume runs and high-quality parts are produced with little or no damage to the dies. Thousands of parts can be manufactured without interruption.

Quality Assurance:

Stamped parts are extremely accurate as a result of the tooling process. Quality is also assured with routine checks throughout the manufacturing process.

Progressive Die Stamping Results in an Overall Lower Cost Per Part:

Due to the combination of all these aspects mentioned above, a lower cost per part is ultimately achieved from progressive die stamping.

Considerations When Sourcing Progressive Die Stamping Parts

Precision Stamped Parts

The Shape of the Part:

The shape may not be able to be manufactured if the tolerances provided are too tight. The form, width, and full size of the part shape determine the recommended tolerances.

The Material Used for Stamping:

The material selection will be decided by the end product’s function and the strength and resistances it will require.

The following materials are frequently stamped:

• Steel that has been hot rolled

• Steel that has been cold rolled

Part Thickness and Size:

Complex parts consist of punching, forming and drawing to create parts of various sizes and thicknesses.

Due to the wide range of complex parts that can be stamped, the manufacturer’s machining capability is an important factor to consider. Do they have the capabilities to stamp larger parts with various degrees of thickness?

Tooling and Order Volume:

It should also be an important consideration that the manufacturer has the tooling capability to make the parts and then be able to deliver volume orders. If the manufacturer cannot deliver the quality and volume required, this is going to affect the OEMs product line and overall output.

Progressive Die Manufacturing For Your Components

Precision stamped parts for Ireland, the UK & Europe

Donlouco Ireland Ltd has a proven track record for quality and sustainable supply of precision stamped parts to customers in Ireland, the UK & Europe. Supplying many different types of parts and components that are punched, formed, deep drawn etc. to automotive and electromechanical industries.

All components are manufactured from excellent grades of raw materials with full traceability from the steel mill and smelting facilities to the finished product, including plating to international standards.

progressive die metal stamping

Donlouco has a wide range of capabilities that ensures manufacturing precision-stamped component parts are well planned out from the tooling stage to quality testing, delivering samples and volume production.

Progressive Metal Stamping China

Sourcing parts in China has become more reliable for companies in recent times. Donlouco Ireland is a company you can rely on, safe in the knowledge that security of supply can still be achieved in the short, medium, and long run. We consistently help our customers to achieve cost and quality targets at all times.

Donlouco Manufactures Precision Parts for a wide range of industries including automotive and electromechanical components.

Types of Precision Stamped Parts We Manufacture:

Precision Stamped Parts.

Fine Blanking and Formed Parts.

Interlocking Parts.

Deep Drawn Parts.

Rolled Housings.

Connector/ Terminal Pins.

Precision Spacers.