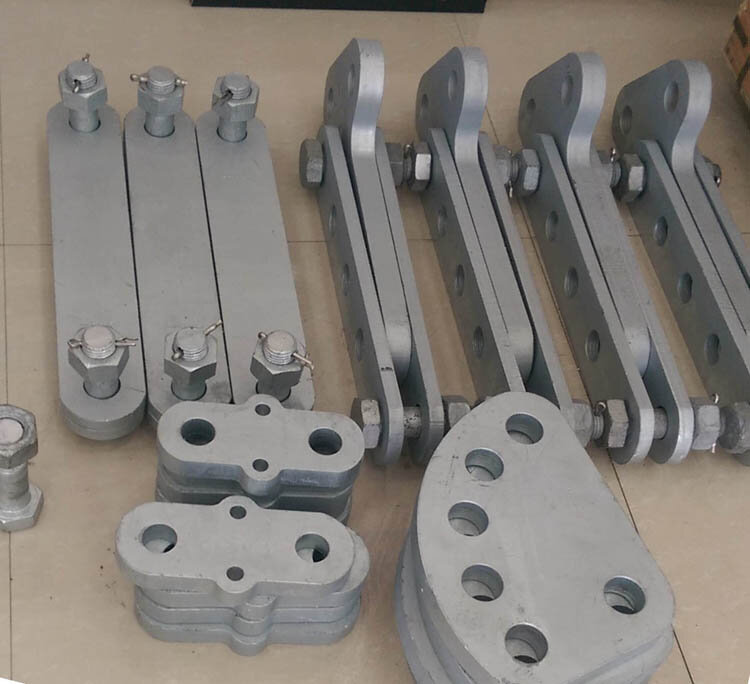

Wide Range Of Engineered Parts In Many Different Grades Of Materials

Donlouco Ireland has the capabilities to manufacture a wide range of engineered parts in many different grades of materials. From steel, stainless steel, aluminium, brass, bronze, and zinc. All parts are shipped with:

Dimensional report for sample check of parts.

Raw material certificate for material used to make parts.

Finishing inspection report for finish thickness for example.

Types Of Materials Used

There are many different types of materials used in the manufacture of engineered parts and even within each category there are many different grades again. Virtually all of these engineering materials are never used in their basic form and are mostly mixed with other metals and elements to form alloys of the basic material. All materials harden when worked on in various processes, particularly when cold. When hardened the material also builds up internal stresses which can only be removed or relieved by a heating process called annealing. The opposite process is called tempering or hardening which is done by heating and then cooling very quickly or in a controlled way.

The General Types of Materials Used:

Steel-Stainless Steel

Aluminium

Brass

Bronze

Zinc

Steel

Steel is the most common type of engineering material used in the world today. Steel is manufactured from Iron which is mined out of the ground mainly in Australia, Brazil, and the USA. Steel is made in a huge number of grades and is manufactured to many different quality standards. It is used to make many other materials like stainless steel. All steel is prone to rust, but the levels depend on the type. For most applications, the steel will require some form of protection to prevent rusting. Steel is categorised or graded by a couple of key characteristics like strength and toughness but other qualities can be equally important depending on the use of the material.

Steel is processed into basic shapes at the steel mill and is then processed into further shapes as part of the manufacturing process thereafter.

The basic shapes are:

Sheets.

Section, H or I sections and bars (Large).

All of these sections are known as hot-rolled as they are formed while the steel is hot. These sections end up with a black scale on the parts which offers temporary protection to the steel against rust. Other, generally smaller sections can be a bright finish which basically means the steel has been formed into its finished section when cold so the steel will not have any black scale and be bright and have a higher tolerance and accuracy. Most steel in China is hot rolled and most of our parts use HRS. Cold rolled steel will have higher internal stresses due to work hardening and has limited applications and generally for more delicate work.

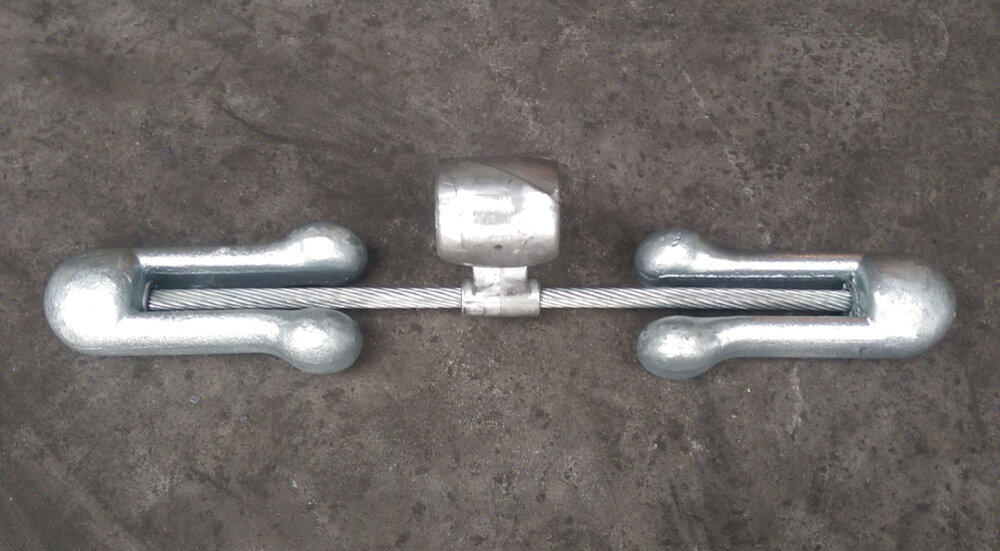

Donlouco manufacture steel parts for the Power Transmission and Distribution Sector in Europe and the UK.

Stainless Steel

Stainless Steel is made from steel by adding elements to the steel when in a molten state. The primary element added to make stainless steel is chromium. Chromium is an extremely hard material and is very wear-resistant and will not corrode. The more chromium added to steel the great the hardness, corrosion, and wear resistance. Another element controlled in the alloy is Nickel which also affects the performance of the material. The most basic grade of stainless steel is 301 but the most common grades are 303, 304, 316, and 316L.

Donlouco supply stainless steel parts the methods of Stamping, Punching, Forming and Deep Drawing.

Aluminium

This is an extremely common material used in a huge number of applications in common day use today. From aluminium foil to wrap food to cooking containers to aircraft parts to engine blocks for cars etc. The material is made from one of the most common ores available in the world called bauxite. But while the ore is common the extraction of aluminium is expensive and requires a lot of energy and can only be purified by a process called electrolysis requiring a vast amount of electricity. The main properties of aluminium are that it has an excellent strength to weight ratio which makes it ideal for many applications but it has also many other key properties like corrosion resistance, machinability, stability, and availability.

Brass

Brass is an alloy of copper and zinc and is often confused with bronze which is an alloy of copper and tin. Both materials corrode in the air and lose their shine very quickly. Brass will go dull and the amount of dullness depends on the percentage of tin in the alloy. The same can be said of bronze which goes a green-black colour when exposed to air.

Both materials can be cast into complex shapes but Brass in particular is made into sheets and bars for engineering uses. Brass in general has good corrosion resistance and has many engineering uses especially in moderate heating and cooling applications and when there is a combination of processes required to make the finished parts like casting and machining. Brass machines very well and has good wear properties.

Finishing

We offer many types of finishing depending on customer requirements.

✓ Plating

✓ Hot Dip Galvanising

✓ Painting

✓ Dipping

✓ Sand Blasting

✓ Shot blasting