Donlouco is Your Reliable Manufacturing Partner in China.

outsource production to China with Confidence

Manufacturing parts in China has recently become much more reliable for companies. It is now more accessible to deal with trusted manufacturing partners like Donlouco in China that have established supply chain management systems to manage all aspects of the supply chain from tooling to manufacturing and shipping to your door.

Security of supply

Donlouco Ireland Ltd is a company that you can rely on safe in the knowledge that security of supply can be achieved in the short, medium, and long run while also achieving cost and quality targets at all times.

Benefits Of Manufacturing Parts In China with Donlouco.

The key benefits of Manufacturing in China include:

✓ Cost Savings

✓ Greater Production Capability, a Leading Source of Manufactured Product in the World

✓ High Quality Parts Manufacturing and Quality Control Measures

Cost Savings

Material Savings: Sourcing raw materials at lower costs due to China's extensive supply network.

Labour Cost Reduction: Benefiting from China's lower labour costs without compromising on skill and productivity.

Transport and Storage: Optimised logistics and storage solutions reduce overheads, enhancing overall cost efficiency.

Quality Control Efficiency: Lower costs associated with poor-quality parts thanks to rigorous quality control measures.

Greater Production Capability

Comprehensive Facilities: Donlouco’s facilities in China are equipped to handle a wide range of manufacturing processes including forging, casting, CNC machining, turning, and milling.

Expertise in Diverse Manufacturing Methods: Specialisation in forged and cast parts, machining from solid, stamped and sheet metal parts.

Integrated Support Services: With headquarters in Ireland, Donlouco offers seamless customer service, engineering support, and scheduling, ensuring smooth coordination with the manufacturing teams in China.

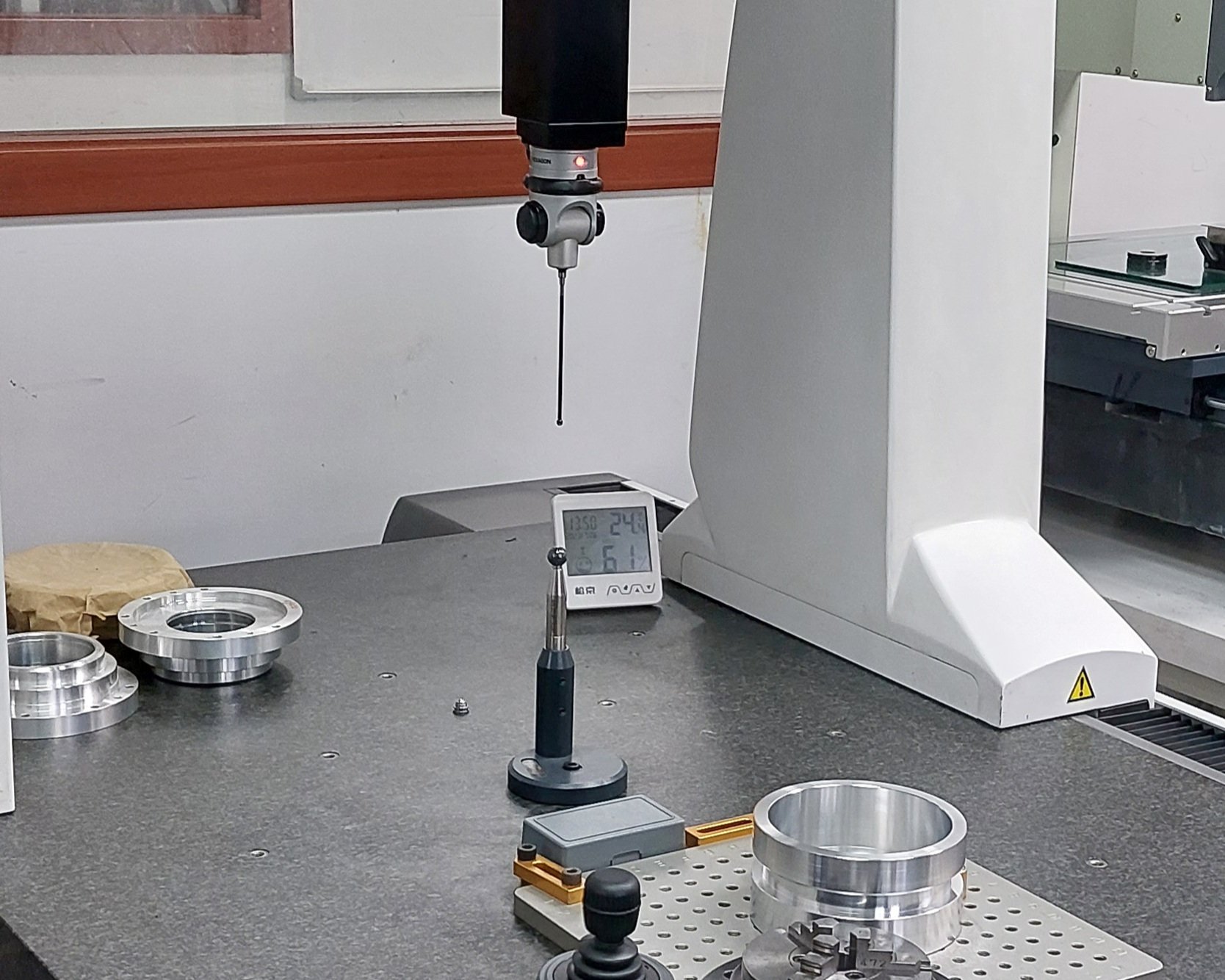

Quality Control Measures

Strict Quality Assurance: Donlouco’s extensive experience in meeting stringent quality and engineering standards ensures that all parts are rigorously checked before shipping.

Independent Testing: Components are independently tested to avoid reworks, rejects, and delays, ensuring that products meet or exceed customer expectations.

Direct Communication: Effective communication channels between Donlouco's engineering teams and Chinese manufacturing staff ensure that customer requirements are clearly understood and implemented.

Donlouco’s Engineers in our Jiashan CNC Facility.

Parts Manufacturing in China FAQs.

-

The industries that manufacture in China vary hugely and can include heavy-duty mechanical components, precision parts, medical products, electronics, plastic products, clothing and textiles.

Through foreign investment, China has earned its place as one of the leading sources of manufactured products in the world and deserves the title of the workshop of the world.

Some of the main trading centres of Shenzhen, Ningbo, Guangzhou, and Shanghai are manufacturing hubs for electronics, chemicals, telecommunications, automotive, steel making and heavy industries.

By accessing the right manufacturing hub for the required products, companies can benefit from the expertise on offer. For example, Shanghai which is China’s financial hub also plays a vital role in the heavy manufacturing industry. They are the largest manufacturers of steel and many multinational automotive companies have set up shop there.

-

Donlouco Ireland Ltd is a manufacturing & engineering services company managing supply chains and costs from design to production in the Far East delivering to Ireland, UK & Europe.

We specialise in complex customer-specific parts where costs are critical, and performance guaranteed.

It has always been a key goal of ours to alleviate the stress and uncertainty of dealing with trading companies, sourcing agents, and even directly with suppliers themselves.

We are experts in forging, casting, CNC machining, turning and milling, working mainly in industrial hydraulics, automotive, utility and equipment manufacturing sectors.

-

Typically, most of our parts are delivered to our customers in shipping containers. There are two basic container sizes, a 20-foot and a 40-foot. Because most of our parts are steel, we are limited by the weight restraint of the shipping container. The 20-foot is about 23 tons and the 40-foot is about 26 tons.

We can also consolidate shipping: There is a belief among many customers that you need to order a container load from suppliers which you might have to do if you’re dealing directly with a supplier in China. Still, we can consolidate different customers’ requirements into one container in China and then ship.

-

There are always risks associated with outsourcing. Donlouco understands this. We know too well from our current customers’ accounts how working with trading companies, brokers and agents can start off well with the initial batch of parts meeting expectations. But it is not long before the quality drops off and you are then left with parts that have been rejected and now have to be scrapped. If you are lucky, they may be reworked.

Donlouco takes the time and effort to understand the exact needs of a customer and deliver parts made from approved raw materials that pass all necessary quality tests. Our track record over the past 15 years speaks for itself, maintaining long-term business relationships with many different companies.

With Donlouco you secure quality control at all stages of the manufacturing process.

Donlouco can offer its customers the following Key Quality Advantages:

✓ Having qualified engineering and quality staff in China that are working directly for Donlouco with suppliers.

✓ Ability to check parts prior to shipping.

✓ Ability to independently test parts in China.

✓ The ability to project manage tools and prototypes in China.